The polymer mixing process: machines and innovations

Polymer mixing is a fundamental process for many industries, enabling the creation of materials with unique properties suitable for a wide range of applications.

Whether it’s to improve the strength, elasticity or durability of materials, the mixing process plays a crucial role.

In this article, we look at the machines suitable for this task, their integration into production lines and the latest innovations in the field.

What is the purpose of polymer mixing?

Material blending is used to optimise production processes by ensuring a homogeneous distribution of components. The process also allows unique blends to be created by incorporating various additives such as colourants, stabilisers or fillers.

These blends are essential to meet specific requirements such as heat resistance, elasticity or impact strength.

Machines adapted to mixing

The choice of polymer mixing equipment depends on the volume of material to be processed and the technical specifications of the end products.

Here are the main types of mixers used in the industry:

Internal mixer

Internal mixers are particularly effective for more difficult materials.

Two versions are used:

- Intermeshing rotor: Used to maximise the dispersion of the components, it produces a homogeneous mixture by applying a high force during mixing.

- Tangential rotor: This type of rotor is used for materials requiring higher shear rates, such as hard elastomers, to ensure efficient deformation of materials and optimum dispersion of additives.

Two-roll mill

Roll mill are widely used in industry for their simplicity and efficiency in mixing materials. There are two main types:

- Laboratory Roll Mill: Used for small quantities of material, these machines are ideal for research and development. These machines can be used to test new mixes and study the behaviour of materials before going into full-scale production.

- Production Roll Mill: Suitable for larger volumes, these mill ensure the homogeneity of production batches. They are often used in the manufacture of rubber, silicone and other polymer products.

Integration of roll mill into production lines

Roll mills are often the first step in the manufacturing process. After mixing, materials can be fed directly into additional equipment such as extruders, calenders or presses.

This allows materials to be formed to the desired dimensions and properties.

Integrating these machines into a fully automated production line not only improves productivity but also ensures consistent quality.

Modern systems offer advanced automation options, limiting human intervention to monitoring and quality control.

Innovations in polymer mixing

The polymer compounding sector has seen the emergence of new technologies aimed at improving the precision and efficiency of the production process.

Here are two key innovations developed by Lescuyer & Villeneuve:

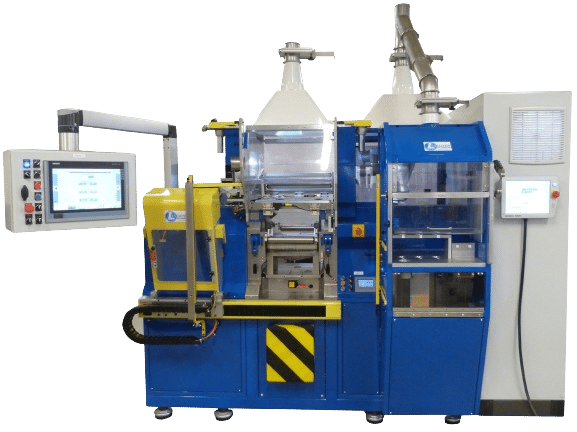

The VOMERY system

This innovative system, patented by Lescuyer & Villeneuve, makes it possible to fully automate the mixing process, particularly for rubber.

The motorised rubber limiters move the material precisely over the cylinders, eliminating human intervention and reducing repetitive manual tasks for operators.

As well as improving productivity, the VOMERY system guarantees more accurate and reproducible blends.

Nanomaterials mixer

With the increasing use of nanoparticles as additives, Lescuyer & Villeneuve has developed a nanomaterial mixer that confines the process within a safe enclosure.

This system limits the diffusion of potentially harmful particles into the air and guarantees the safety of the operators. Combined with a robotic arm and the VOMERY system, this mixer makes it possible to process complex mixtures while minimising risks.

Conclusion

Polymer mixing, whether using roller mixers or internal mixers, remains a key process for many industries.

Recent advances, such as the VOMERY system and the nanomaterial mixer, reflect a constant drive to optimise processes and meet growing demands for safety, efficiency and precision.

These innovations enable companies like Lescuyer & Villeneuve to position themselves as leaders in polymer processing.