Co extrusion: an advanced technology for polymers

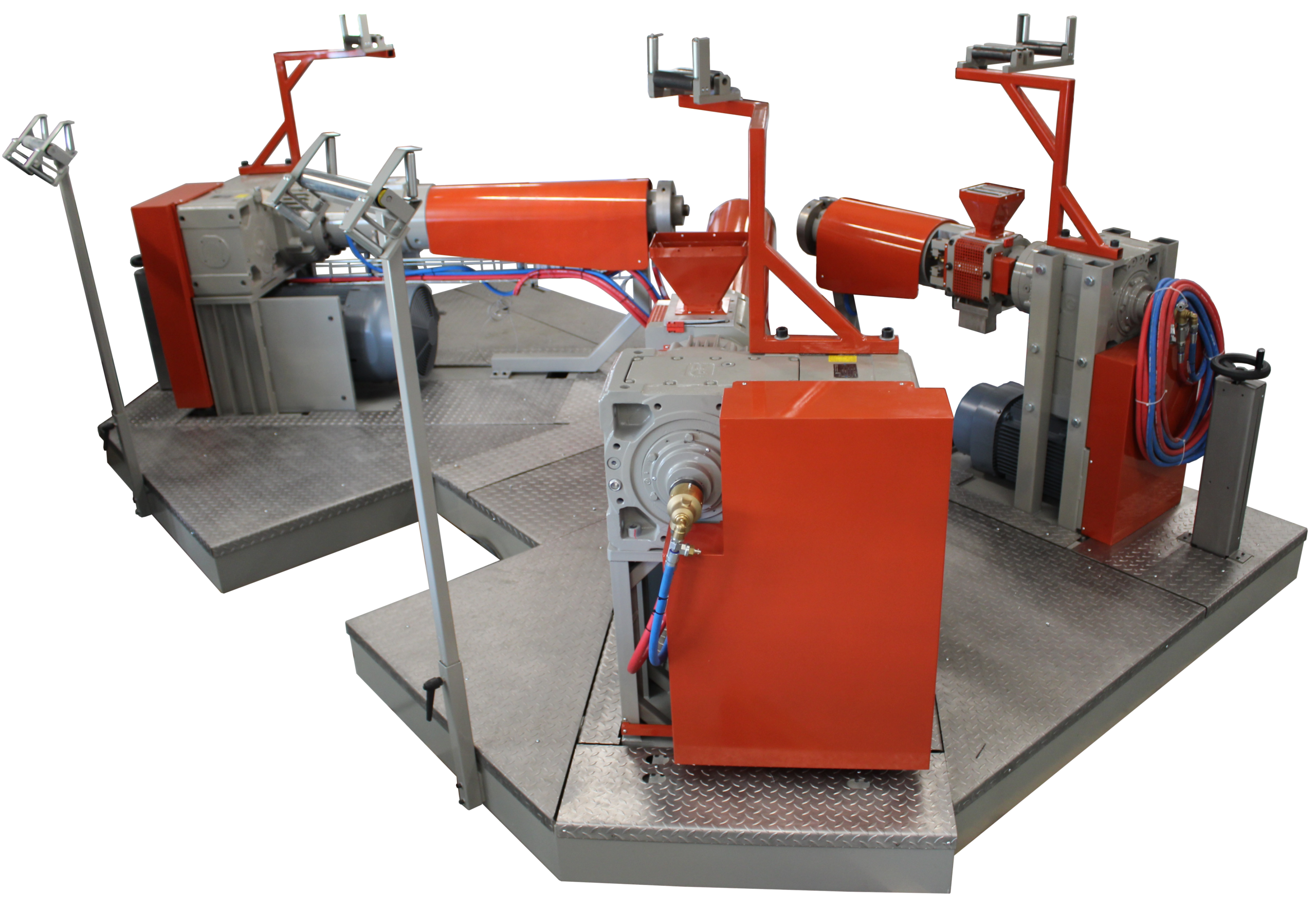

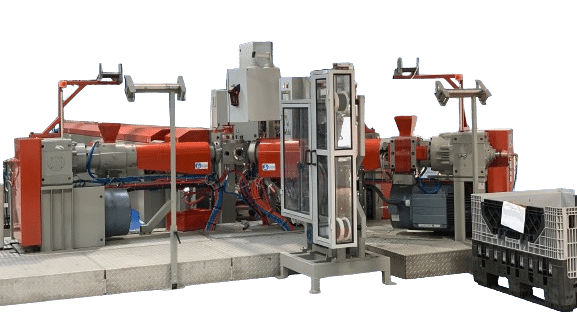

Co extrusion is an advanced process that allows multiple polymers to be combined in the same production stream to create multi-layer products with specific properties. The process involves the use of multiple extruders, each feeding a separate stream of molten polymer.

These streams come together in a single die where they coalesce to form a homogeneous multi-layer structure with unique properties.

A competitive advantage

This process is particularly useful for creating composite products with specific characteristics, combining the properties of different materials in a single part.

In the context of rubber and elastomer extrusion, co extrusion makes it possible to obtain products with improved properties, such as better wear resistance, improved sealing or improved durability.

How does co extrusion work?

The co extrusion line is equipped with a number of feed channels, which feed different materials into the extruder. Each stream comes from its own extruder, which heats the material before sending it to the die. The streams flow through different channels before meeting and mixing at the complex die geometry. The thickness and composition of each layer can be adjusted as required.

This process allows multiple layers to be applied to the same product, offering great design flexibility. For example, a tube could be made with an inner layer of rubber for flexibility and an outer layer of plastic for UV or oxygen resistance.

Necessary expertise and applications

To ensure stable production, the common structure of the co extrusion extruders must be designed to minimise pressure losses in each flow channel to ensure consistent quality of the finished products.

There is has a wide range of applications in different industries.

In the automotive sector, for example, it is used to produce seals that combine flexibility and rigidity. In the packaging sector, co extrusion is used to produce multi-layer films that offer a better barrier against moisture and gases, thus ensuring the preservation of food products.

Properties of coextruded products

The products resulting from this process have a number of mechanical and functional characteristics, including:

- Excellent adhesion between layers: The fusion of the polymers at their contact zones ensures a strong bond between the different layers, creating a homogeneous structure.

- High shear resistance: Co extruded products are particularly resistant to deformation and breakage.

- High elongation resistance: These products can withstand a large amount of deformation before breaking, which is particularly useful in applications where flexibility and resilience are required.