Our expertise

100 years of experience and know-how, what does it add up to?

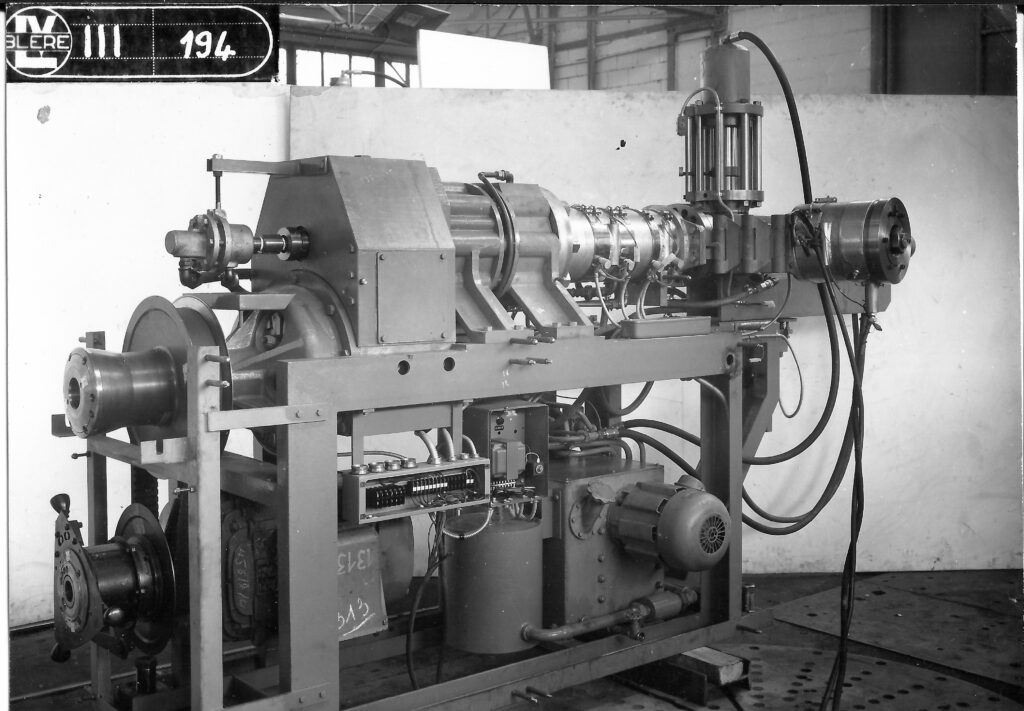

Founded in 1923, Lescuyer & Villeneuve has demonstrated a remarkable ability to adapt to an ever-changing environment, constantly subject to the imperative of innovation.

Its ability to persevere over the decades since 1923 is an undeniable testimony to its expertise and know-how, but how does this translate into concrete action within the company?

Discover in detail the three elements that shape Lescuyer & Villeneuve’s image as a trustworthy company

Technology

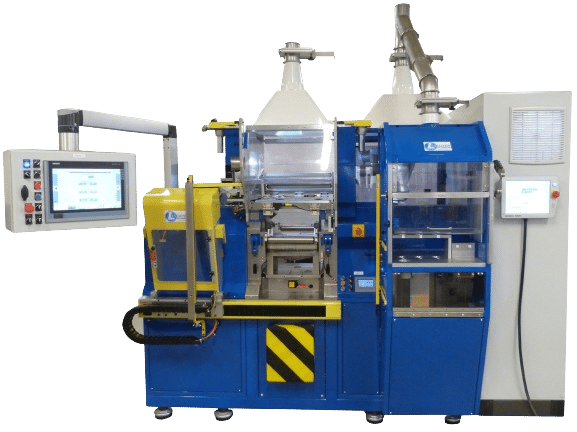

Lescuyer et Villeneuve’s electrical offering stands out from the crowd. Preserving the purity of mixtures in the face of the impact of processing equipment is a crucial concern for laboratories and various production units.

Lescuyer et Villeneuve sets itself apart by adopting electric technology without the need for a centralized lubrication system across its entire product range. In addition, the company has developed patented technologies designed to meet future challenges, particularly in the field of nanomaterials.

Notably, Lescuyer et Villeneuve has developed a roll mill specifically designed for nanomaterials, meeting tomorrow’s needs in terms of operator safety and respect for the environment.

In this quest for innovation, it is imperative to take emerging environmental issues into consideration, in order to design sustainable equipment that will comply with future regulations.

Innovation - R&D

The innovation-driven company is always on the lookout for new challenges, and actively participates in numerous French and European calls for projects. As a member of the rubber industry competitiveness cluster, Elastopole, it has developed a lot of technological innovations since 2014, seven of which have been patented.

Lescuyer et Villeneuve maintains a technological lead in rubber processing by continually innovating to modernize machines whose design has remained unchanged for several decades. To this end, its teams are turning to electric motorization, the use of thermal and laser cameras, innovative safety systems, and full automation to achieve a unique degree of precision.

Customized solutions

The challenges you face in production or laboratory processing can be solved thanks to the expertise of our design departments.

Our approach is based on a comprehensive package that supports you for every stage of the design process for equipment or complete production lines. Our teams are perfectly equipped to propose and design innovative solutions that precisely meet your specific needs.

What sets our approach apart is our ability to carry out customized studies, in close collaboration with your engineers and machine operators.

This close collaboration enables us to develop solutions that not only solve your current problems, but also anticipate future challenges in your field of activity.